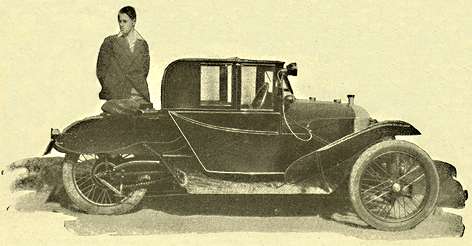

The Grand Prix Morgan does not loose its sporting appearance as a coupé.

The Grand Prix Morgan does not loose its sporting appearance as a coupé.

The Morgan was a Grand Prix model with a M.A.G. water-cooled engine and electric lighting; it was purchased second-hand in July of 1924. After a thorough overhaul shortly after purchase the machine has run consistently for three years, and so far has given absolutely no trouble whatever. The work of the coupé portion was begun just after Christmas two years ago, and was finished a few weeks after the Easter of 1926. I myself worked in the capacity of designer and labourer, while my father was good enough to do all the woodswork.

Building the Coupé

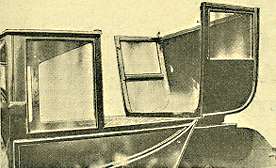

The first problem which faced us was how to get in and out of the Morgan, assuming that it could be enclosed; as we did not relish the job of splitting down one of the steel side panels to fit a door a compromise was made by making a back which folded over towards the rear. Thus an entry is made by stepping over the rear.We first started on the front portion, and began by making a V-shaped screen exactly one inch higher than the original, which was scrapped. This new screen was made a good fit over the bonnet, as it was intended to take a good deal of the strain of the new top; it was made in two portions, with a screen to open outwards in each half, and was fixed in the centre, as well as by screws, to the oak uprights which formed the framework of the new sides.

We got over the task of filling in the curved sides of the original body by making an oak framework which had a rail giving a straight line from the highest point on the backrest to the dashboard and at the same time formed the lower rail for the side windows. The lower portion was then enclosed by a panel of three-ply wood, with a suitable beading. The side windows are roughly 10in. wide, and the overall width of the framework, measuring from screen towards the rear, is about 14in., so that it will be seen that there is plenty of room, even though the front portion is fixed to the body. An oak rail across the rear uprights and a light section rail along the top centre to middle of screen served the purpose of giving a central fixing for this half roof, which was also made of three-ply.

When this front portion was fitted all joints were thoroughly glued and screwed, and the side windows lined with rubber to take up any looseness and to prevent rattle. The method used to fit this portion to the body itself was as follows. The screen was fixed by screws underneath the dash; long screws were used through the side panels into the front oak uprights, and a bolt was passed through a hole in the panel, which originally held the main hood support. This held the rear upright, in addition to which there was a 1½in. wood screw a little lower down the panel. Although this fixing may not appear very sound, in practice it proved to be absolutely rigid.

The Rear Portion.

With this part finished the work on the rear portion was begun, and it proved rather a delicate job, requiring much patience. The curved rails were part of the original hood sticks, and the job of fitting the three-ply over the curved back needed three people; two held the three-ply to the required curve while the third put the screws in place. This also applied to the fixing of the 1½in. bead round the edge of this portion, for which a pair of brass hinges about 3in. long were used. These long screws were fixed to an oak rail, which in turn had been bolted to the top of the back rest. For the side windows in the rear half we used celluloid, as this was considered safest in case of accident; but all the other windows were of ¼in. plate glass.All the woodwork, when finished, was carefully sandpapered, and the inside was afterwards given a coating of size and finally finished with carriage varnish, the idea being that as the three-ply was mahogany and all the rest oak, the varnish in conjunction with natural grain of wood would give an excellent finish.

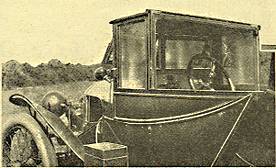

Two views of the Morgan with the coupé raised.

The outside of the body was then tackled, and after a very tedious job of rubbing and cleaning down of old paint it was given two flat or undercoats of Robbialac paint, and afterwards a coat of enamel; finally a coat of varnish completed the finish. Although this was my first attempt at coachpainting, the Robbialac finish looks well, even after a hard wear. I followed instructions and took my time, and I think that the finish obtained well warranted the trouble taken.

Perhaps the most difficult job was painting the black edging or bead, which is used to divide the various panels; to get a fairly straight line is difficult and takes time but in the end it was well worth it.

The hand brake had now to receive attention, for as it was enclosed I was unable to use it in the old position, so I decided to construct one on the ratchet principle, and I made a bracket to take this and the gear lever in one fitting. On the this also has been quite a success, and the levers fall naturally to hand.

I scrapped the old bar fittings to both brakes and substituted ¼in. wire cable; by this means I have quite overcome the annoying rattle which was a drawback to the older pattern.

With the machine finished I have given it over a year's good running, and so far have not found any fault with the new design except, perhaps, for a slight drumming, which I believe exists in even good-class cars.

The latest improvement I have added is new seating accommodation, for I have found that the cushion previously used was uncomfortable after 150 miles or so. New seats of the deck-chair type are made of the same material; each is independent of the other and is suspended from six springs. To fix these I screwed six stout screw eyes in the back rest, and in each eye I hooked a spring. Using a length of mild steel to which the canvas seats were already attached, I hooked this to the other end of the springs, and all that remained to be done was to fix the forward end of the seat in some convenient way. These have answered their purpose so well that my passenger on our last run north went to sleep for at least an hour.

As is well known, the Morgan is a handy little machine, easy to control, gives excellent service if properly attended to, and is economical to run. With the improvement to the body which I have effected it is, in addition, ideal in all weathers.

R. J. H.