front-page

back-page

front-page |

back-page |

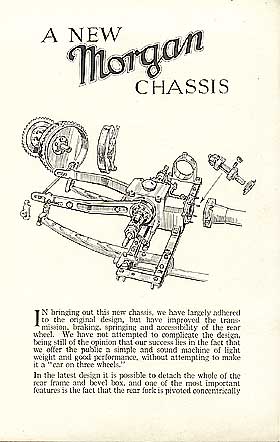

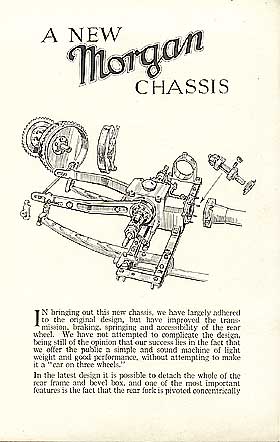

In the latest design it is possible to detach the whole of the rear frame and bevel box, and one of the most important features is the fact that the rear fork is pivoted concentrically with the cross-shaft. Two other features are the provision of bevels adjustable for mesh and the employment of a large internal-expanding rear wheel brake, having shoes 8in. in diameter and 1½in. in width.

Forged steel fork members are pivoted directly on the outside of the bosses, in which the cross-shaft ball races are mounted. They have a very large bearing area at this point, and they are remarkably sturdy in construction. The rear wheel is held in position by a knock-out spindle, with the end of which is combined the rear brake operating cable stop. The wheel is therefore quickly detachable. Instead of superimposed springing, the springs are now carried below the rear fork, and in the case of the super-sports model with the low frame, these springs curve upwards towards the rearward links.

Comfort is greatly enhanced by this arrangement, and the concentrically mounted fork arms should be an ideal arrangement, since it should reduce chain wear to a minimum.

At the end of the propeller-shaft enclosing tube is a flange which bolts up to the bevel box casing, the bevel pinion being mounted in two separate ball bearings spaced by a distance piece. The whole of this pinion unit is adjustable for mesh by means of a screwed end-cap and a taper locking-pin. Similar arrangements are made for the adjustment of the driven bevel wheel and its shaft.

Long centres between the pinion-shaft bearings enable the propeller-shaft to be shortened by some inches, thus reducing the possibility of whip in this part. When the bevel box flange has been uncoupled the U-clips which connect the cross-frame to the longitudinal members may be removed and the whole of the back of the chassis withdrawn.

Since the rear fork is pivoted at the shaft centre, instead of behind it, it has been possible to shorten the wheelbase by three inches without affecting the body space at all, and advantage has been taken of this on the Aero and two-seater models, though the wheelbase of the super-sports and Family models remains the same.

Other features which will be combined with the new chassis consist of a smart vee-type windscreen on Aero models, a sloping screen and bucket seats on Family models.

Incidentally, it has been found possible to provide more room in the rear seats of the Family type.

This chassis will shortly be available for all models at an extra charge of £6 10 0.